Showing 13–24 of 58 results

-

Helium Purity Analyzer BI 610 measures Helium in percent level in process gas. For He measurement Thermal Conductivity technology is used. Easy to maintain and service from user point of view. LCD, LED & Touchscreen display available. Analog 4-20 mA output with 2 nos. potential free relay contact. It has 4 different mounting configurations, Wall, Panel, Rack & Tabletop.

-

Hydrogen Purity Analyzer BI 600 measures Hydrogen in percent level in process gas. For H2 measurement Thermal Conductivity technology is used. Easy to maintain and service from user point of view. LCD, LED & Touchscreen display available. Analog 4-20 mA output with 2 nos. potential free relay contact. It has 4 different mounting configurations, Wall, Panel, Rack & Tabletop.

-

Hydrogen Purity Analyzer BI 620 measures Hydrogen in percent level in process gas. For H2 measurement Thermal Conductivity technology is used. It has long-life, eight-hour battery charge. It can be started up and ready to measure within minutes. It is supported by automatic zero calibration and continuous system diagnostics to maintain excellent analytical performance throughout its operation. Robust and lightweight, is easy to transport and use. Easy to maintain and service from user point of view.

-

The Insitu Zirconia Oxygen Analyzer BI 2100-HH is designed for Combustion Process & Emission Monitoring where flue gas temperature is upto 1600 deg C. It provides accurate measurement of excess oxygen in flue gas of combustion processes. Optimal combustion efficiency is achieved by maintaining the ideal level of oxygen in the flue gas. BI 2100 is best solution for boilers manufacturer with reasonable cost. It can be customize to integrate with various process & site conditions. With no moving parts or sampling apparatus, the analyzer is extremely reliable. Zirconia sensor is very rugged & can withstand high temperature & pressure with life cycle more than 5 years. Online calibration can be performed during operation. The available mode of calibration are Auto Cal. & Manual Cal. BI 2100 series is field repairable. All active components can be replaced, including the filter, sensing cell & electronic card.

-

The Insitu Zirconia Oxygen Analyzer BI 2100-HL is designed for Combustion Process & Emission Monitoring where flue gas temperature is upto 900 deg C. It provides accurate measurement of excess oxygen in flue gas of combustion processes. Optimal combustion efficiency is achieved by maintaining the ideal level of oxygen in the flue gas. BI 2100 is best solution for boilers manufacturer with reasonable cost. It can be customize to integrate with various process & site conditions. With no moving parts or sampling apparatus, the analyzer is extremely reliable. Zirconia sensor is very rugged & can withstand high temperature & pressure with life cycle more than 5 years. Online calibration can be performed during operation. The available mode of calibration are Auto Cal. & Manual Cal. BI 2100 series is field repairable. All active components can be replaced, including the filter, sensing cell & electronic card.

-

Insitu Zirconia Oxygen Analyzer BI 2100-S is designed for Combustion Process & Emission Monitoring where flue gas temperature is upto 700 deg C. It provides accurate measurement of excess oxygen in flue gas of combustion processes. Optimal combustion efficiency is achieved by maintaining the ideal level of oxygen in the flue gas. BI 2100 is best solution for small boilers manufacturer with reasonable cost. It can be customize to integrate with various process & site conditions. With no moving parts or sampling apparatus, the analyzer is extremely reliable. Zirconia sensor is very rugged & can withstand high temperature & pressure with life cycle more than 5 years. Online calibration can be performed during operation. The available mode of calibration are Auto Cal. & Manual Cal. BI 2100 series is field repairable. All active components can be replaced, including the filter, sensing cell & electronic card.

-

Integrated Continuous Emission Monitoring System with SCU & Heated Probe & Sample Tubing

Continous Emission Monitoring SystemThe Continuous Emission Monitoring System BI 7000 is designed in compliance to emission norms to measure gases pollutants emitted by various process industries and to meet the needs of organizations requiring cost effective and reliable multiple gas analyzer solutions. BI 7000 is TUV certified for CE mark & Performance as per EN15267 standard. The technology employed are of maximum reliability and accuracy to ensure high degree of performance & long life. BI 7000 is ideal solution to protect initial investment & can adapt to any process application with modular design & can house up to eight gas sensors with scalable ranges for each gas. Manufactured for use in hostile or friendly environments the BI 7000 Continuous Emission Monitoring System maintains high levels of gas selectivity, all packed into a robust, attractive, industrial enclosure. -

The KCA-25 Series is an advanced Non-Dispersive Infrared (NDIR) Analyzer, meticulously designed for monitoring gases and providing precise data for combustion control in industrial environments. This analyzer plays a vital role in tracking gas emissions, ensuring environmental compliance, and optimizing operational efficiency in various industries. NDIR Analyzers are used to detect and monitor the following gases:

- Oxides of Nitrogen (NO, NO₂, etc.) – collectively known as NOx

- Carbon Monoxide (CO)

- Sulfur Dioxide (SO₂)

- Carbon Dioxide (CO₂)

- Oxygen (O₂)

-

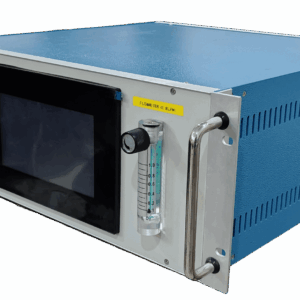

BI7100 Landfill Gas Analyzer is designed to measure the gases like CH4, H2S, CO, CO2 & O2 recovered and processed from Landfill sites. BI7100 Landfill gas analyzer continuously removes moisture from the wet sample gas and comes complete with per-filter, sample pump, flow meter, continuous moisture removal system, long-life O2 CO2 & CH4 sensor alarm relay contacts and 4-20mA outputs for each gas measured.

-

Multi Gas Analyzer BI 7400 is designed to meet the needs of various industrial process with combination of technologies. The technology employed is tried and tested to ensure the user experiences maximum reliability and accuracy. Up to six gases can be analyzed simultaneously with scalable ranges for each gas. BI 7400 is an ideal solution to protect initial investment & long lasting performances.

-

BI 400 Purity Oxygen Analyzer measures Oxygen in percent level in process gas. For O2 measurement Electrochemical technology is used. Easy to maintain and service from user point of view. LCD & LED touchscreen display available. Analog 4-20 mA output with 2 nos. potential free relay contact. It has 4 different mounting configurations, Wall, Panel, Rack & Tabletop.

-

BI 410 Purity Oxygen Analyzer is designed for Oxygen measurement in various application with low drift, precision, accuracy and stable oxygen readings and long life Paramagnetic sensor makes the analyzer worth the investments for long term use. Easy to maintain and service from user point of view. LCD & LED touchscreen display available. Analog 4-20 mA output with 2 nos. potential free relay contact. It has 4 different mounting configurations, Wall, Panel, Rack & Tabletop.