The Continuous Emission Monitoring System BI 7000 UV DOAS is designed in compliance with emission norms to measure gas pollutants emitted by various process industry and to meet the needs of industries requiring cost effective and reliable multiple gas analyzer solutions.

The technology employed are of maximum reliability and accuracy to ensure high degree of performance & long life.

BI 7000 is ideal solution to protect initial investment & can adapt to any process application with modular design & can house up to eight gas sensors with scalable ranges for each gas.

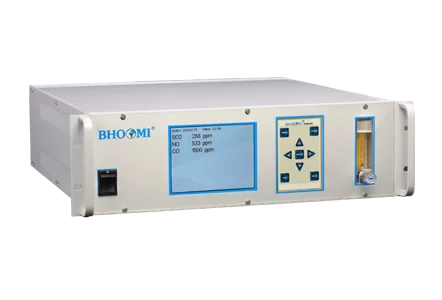

Manufactured for use in hostile or friendly environments the BI 7000 Continuous Emission Monitoring System maintains high levels of gas selectivity, all packed into a robust, attractive, industrial enclosure.